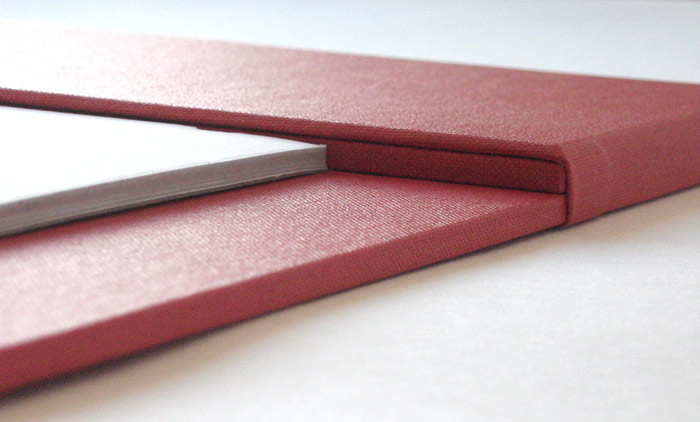

little details - big impact

Any handcrafted book, album, box, folder, portfolio or presentation is a vessel for it’s content. Professional detailing enhances the aesthetic appeal leaving a powerful impression on clients, recipients & viewers.

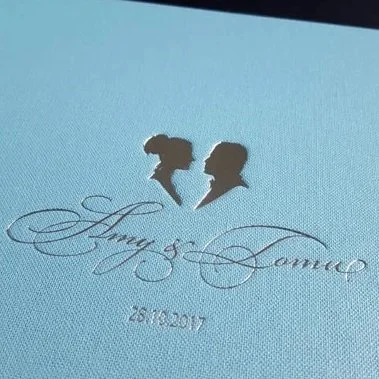

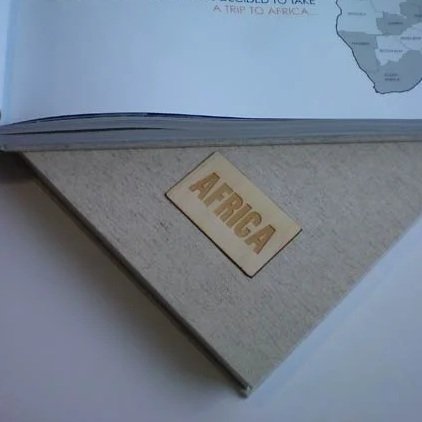

Personalised Touch: Create truly unique gifts or heirlooms with custom initials, dates, or messages

Unforgettable Impact: The tactile & visual quality of a debossed or foil-stamped finish speaks volumes about attention to detail

Brand Recognition: Place your logo or name directly onto your pieces for instant brand recall

Professionalism: Elevate your presentation for client pitches, art exhibitions, or photography showcases

The Binding Studio works with you to ensure your branding vision is perfectly executed. Lou will guide you through the process & help you choose the best option for your project. To discuss detailing & receive a quote read info & files specs for the desired process below.

Contact The Binding Studio to discuss your custom branding needs & add that perfect, professional touch to your handcrafted binding.

The Craftsmanship Bringing Your Vision to Life

Utilising traditional & contemporary techniques, combined with precision- stunning results are achieved on a variety of materials. Explore the range of detailing services below.

-

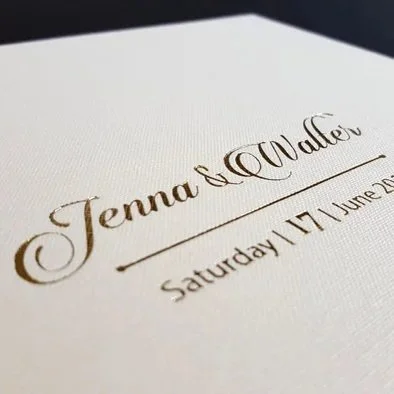

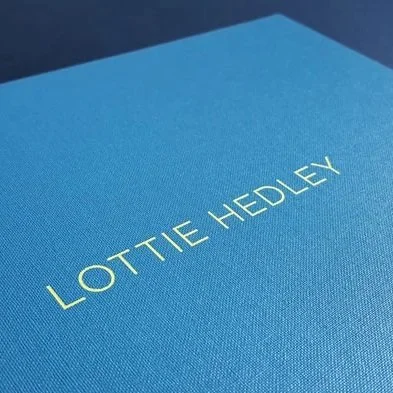

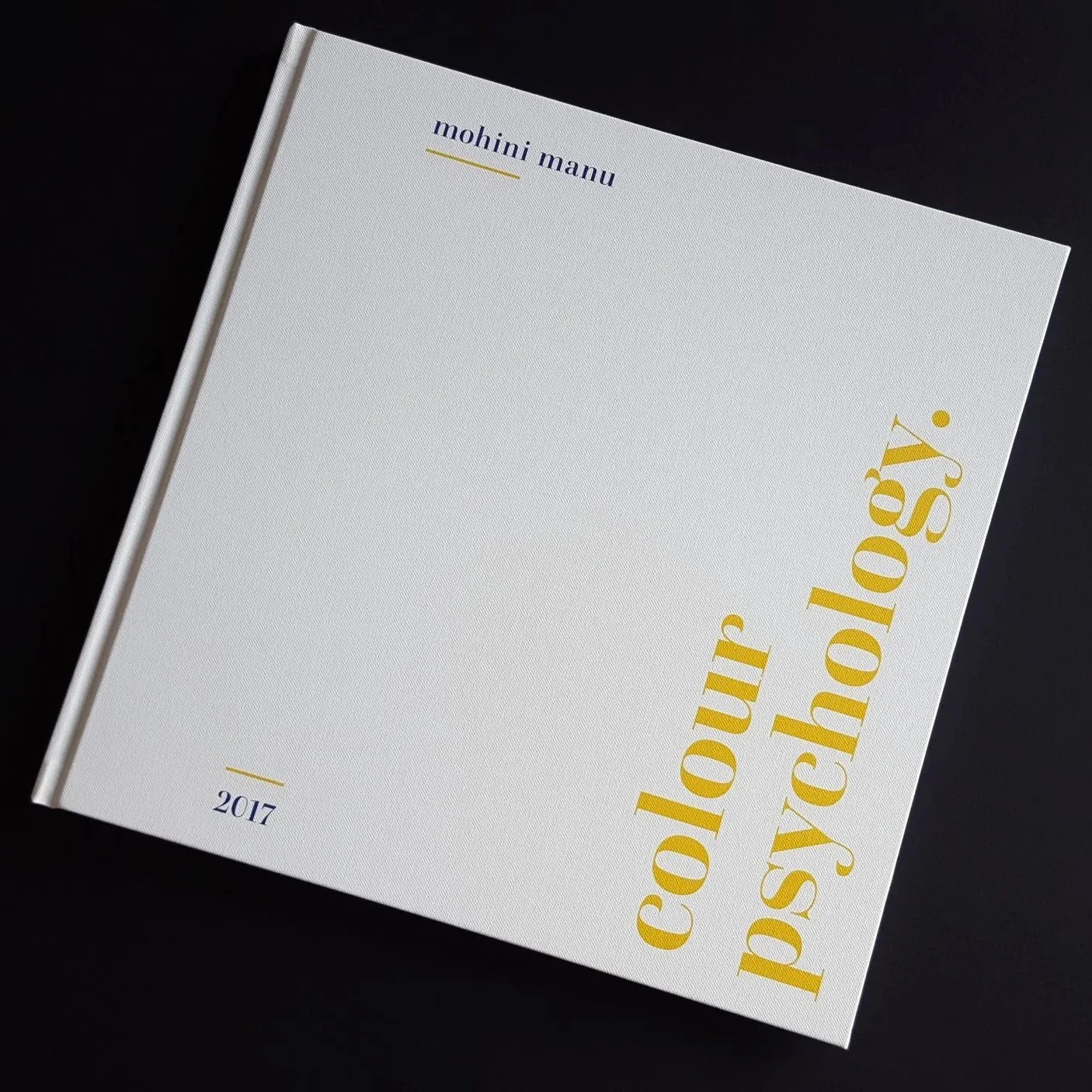

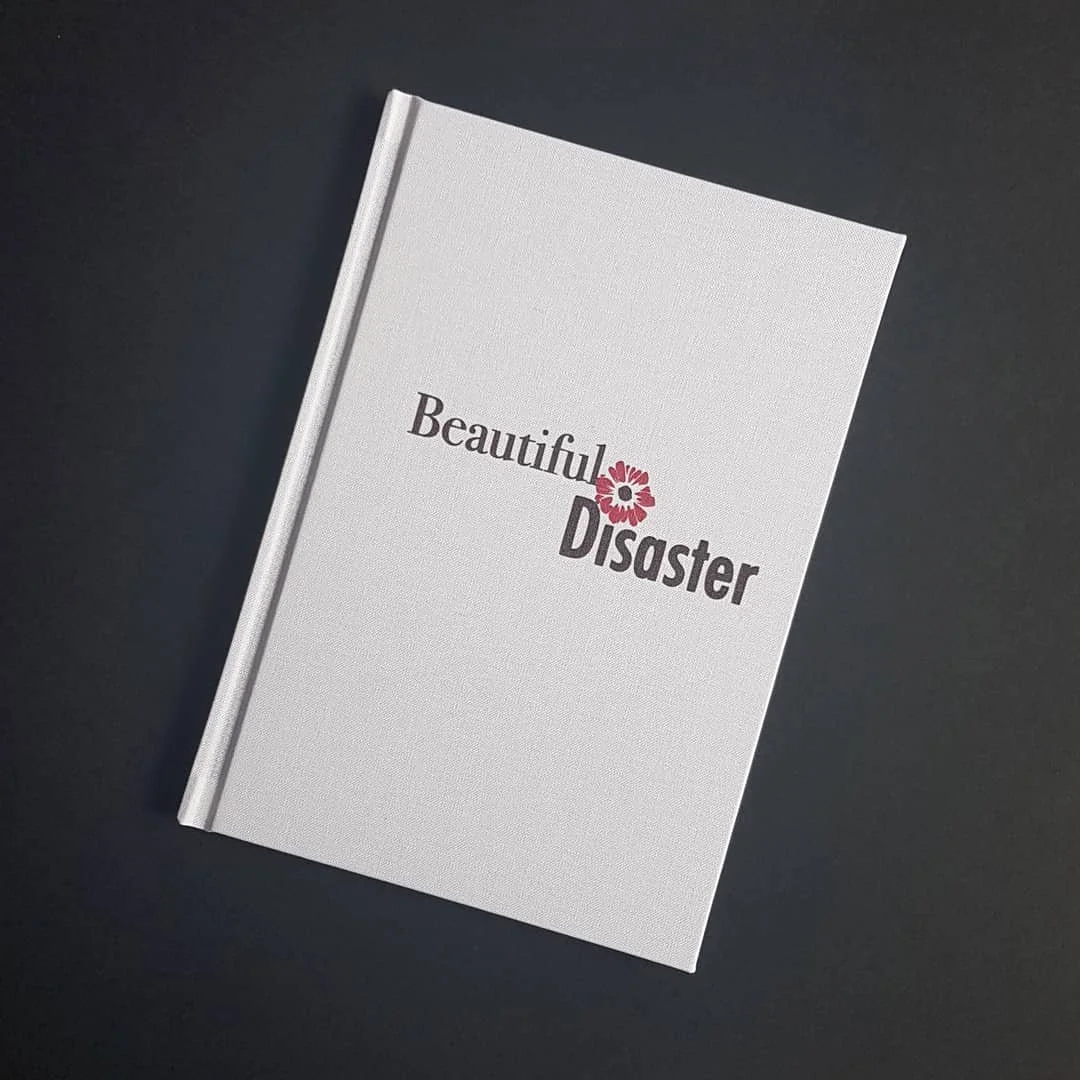

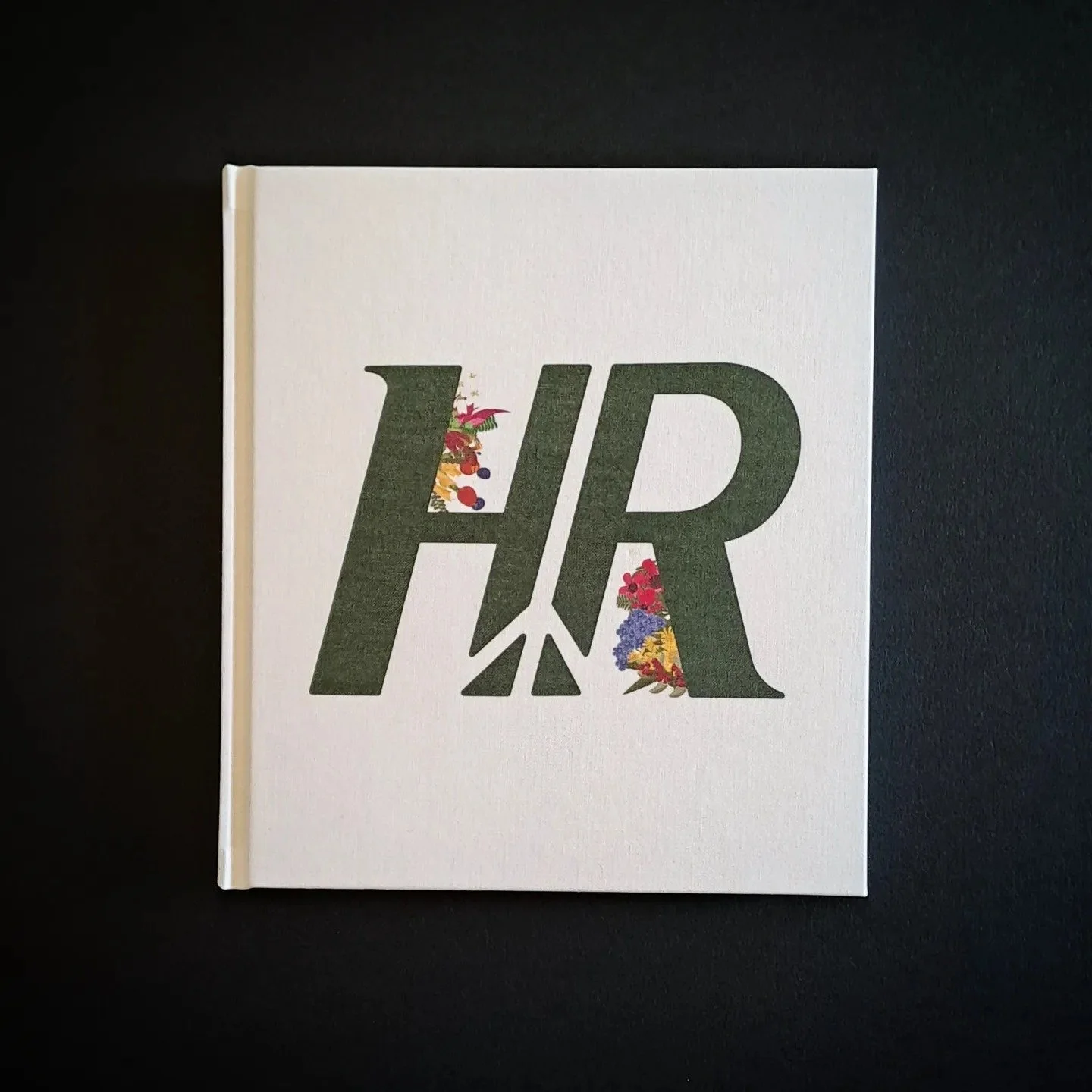

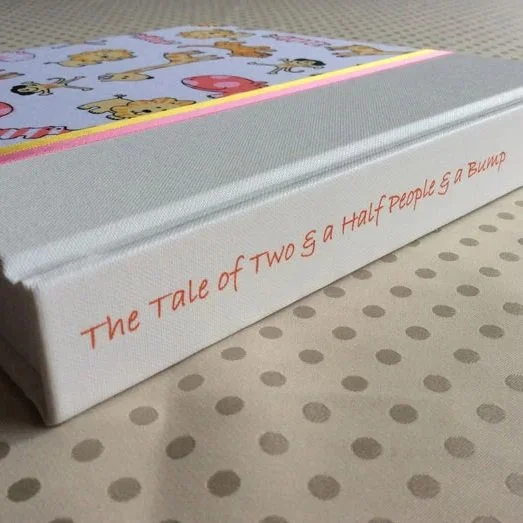

AKA hot stamping / foil stamping / tooling

Foiling involves applying coloured foil to the surface of your material with heat and pressure.

The result is a vibrant and permanent impression that truly stands out. Perfect for titles, logos, intricate designs and a touch of elegance.

You supply a PDF of your custom artwork- The Binding Studio takes care of the rest! To provide you with a quote, Louise needs to view your artwork & know your colour & positioning choices.

THE PROCESS:

A custom metal block is produced from your artwork

The block is attached to a foiling machine

Heat, pressure & foil are applied to “stamp” the block into the cover

THE SPECIFICS:

Foiling is when a colour is added to the sunken part of a pattern, logo, or title

Depth is determined by layout & design

A foil generally feels shallower than a blind deboss

Foil comes in standard colours / pantone numbers are used for colour matching

Multiple colour foils are possible- this requires multiple blocks & set ups

SUPPLYING ARTWORK:

A high-resolution vector file, coverted to PDF of your logo, text, or artwork

Black artwork on “white” background / no colour or grey scale

100% size / the size you want it on your cover

Positioned on your page size / TBS will add the additional for cover measurements

Lines need to be thicker than half a millimetre / advice will be given on viewing artwork

Very detailed designs may need simplifying / advice will be given on viewing artwork

NOTE: TBS has some brass type available for titles and simple wording. This can be used in place of a custom block for foiling. Ask about “TYPESETTING” for the options.

-

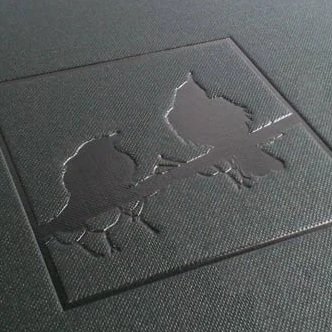

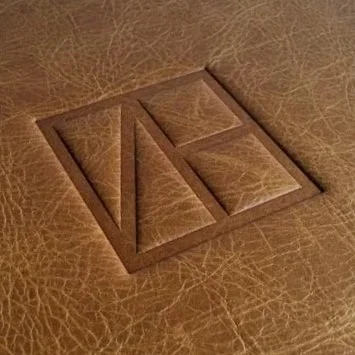

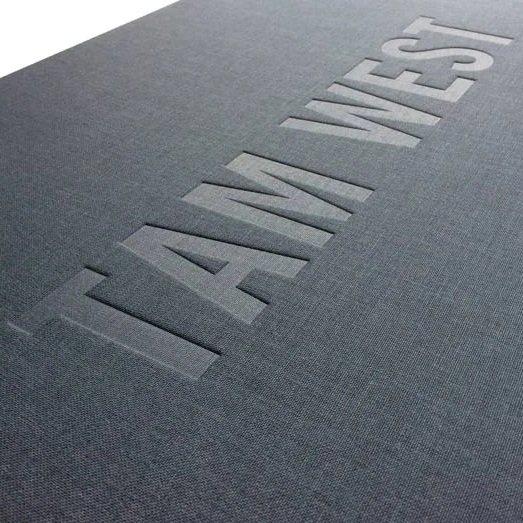

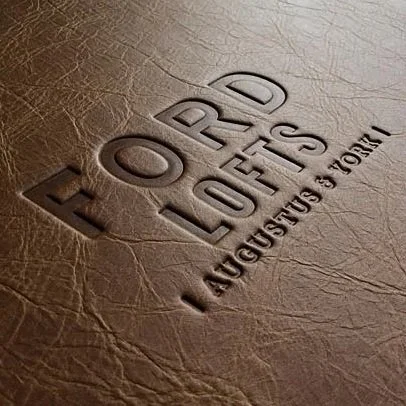

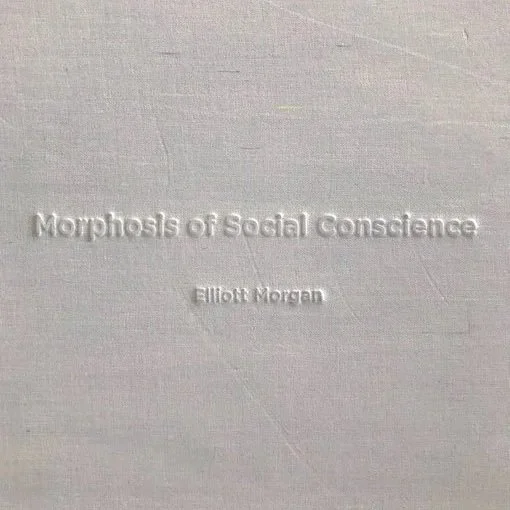

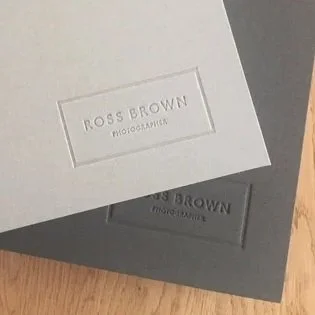

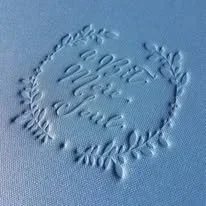

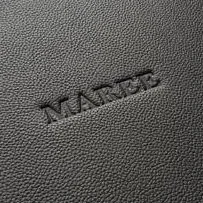

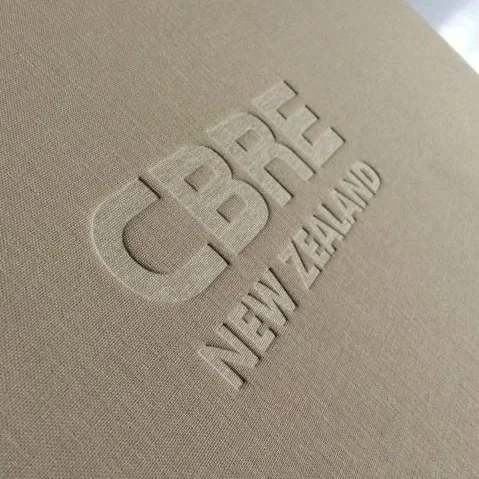

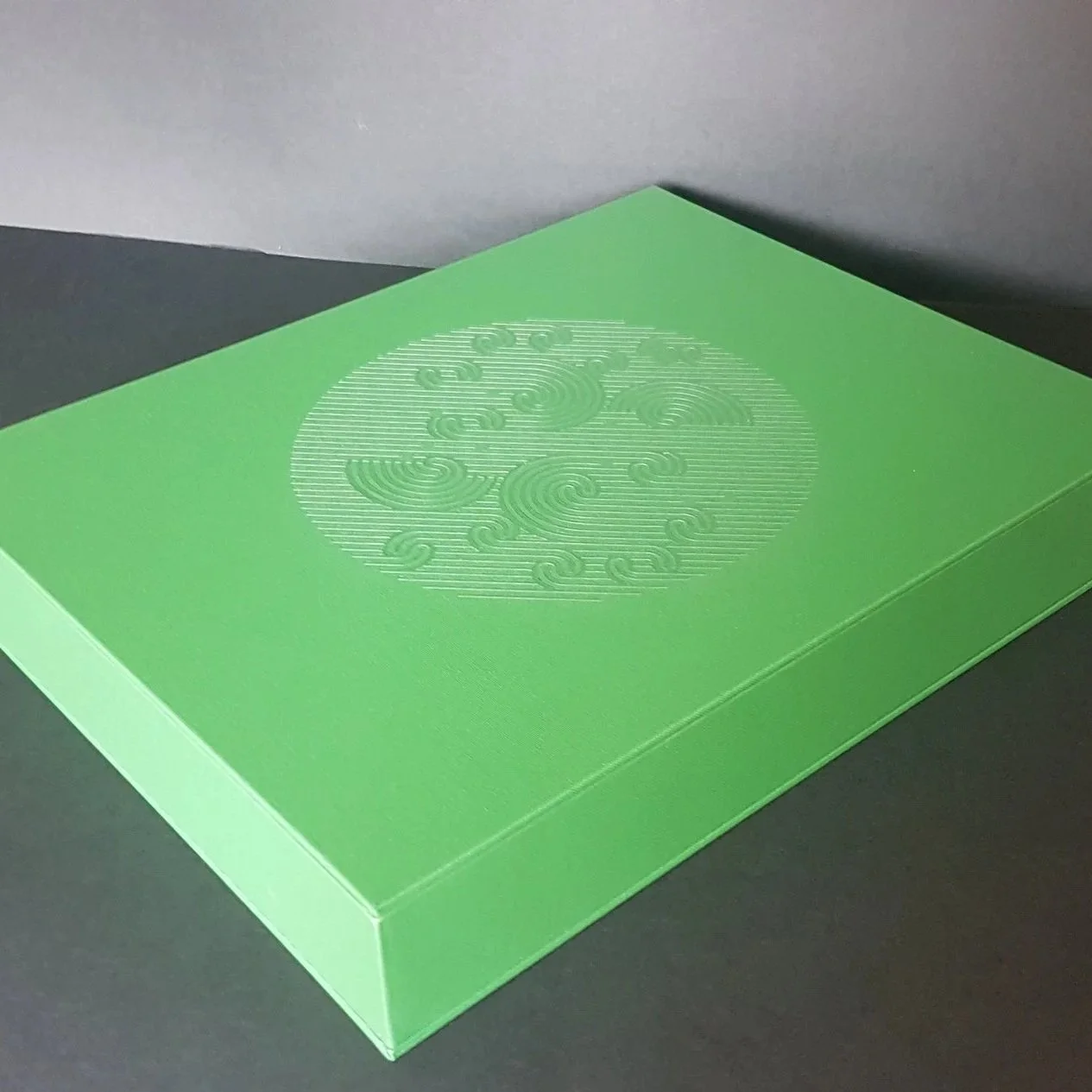

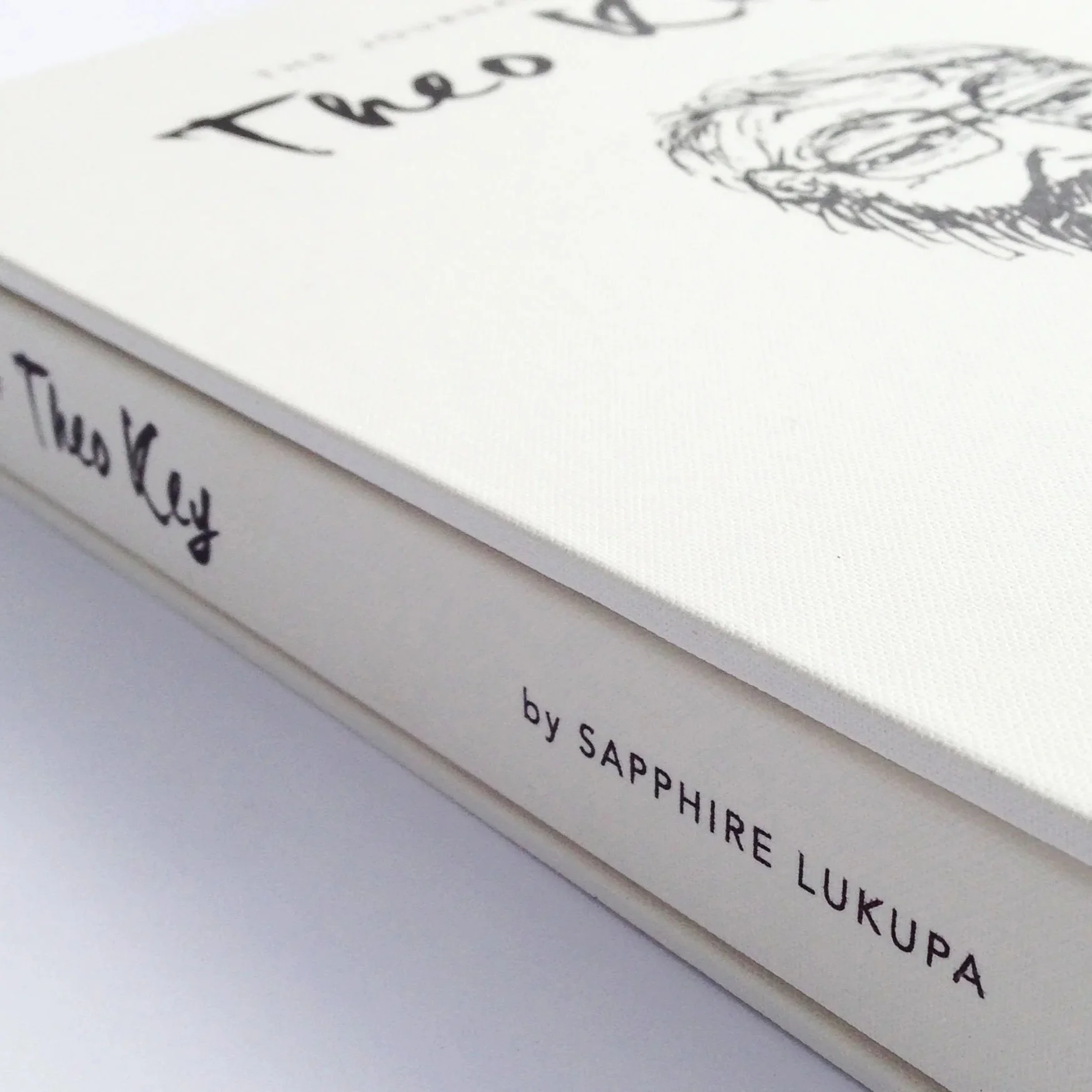

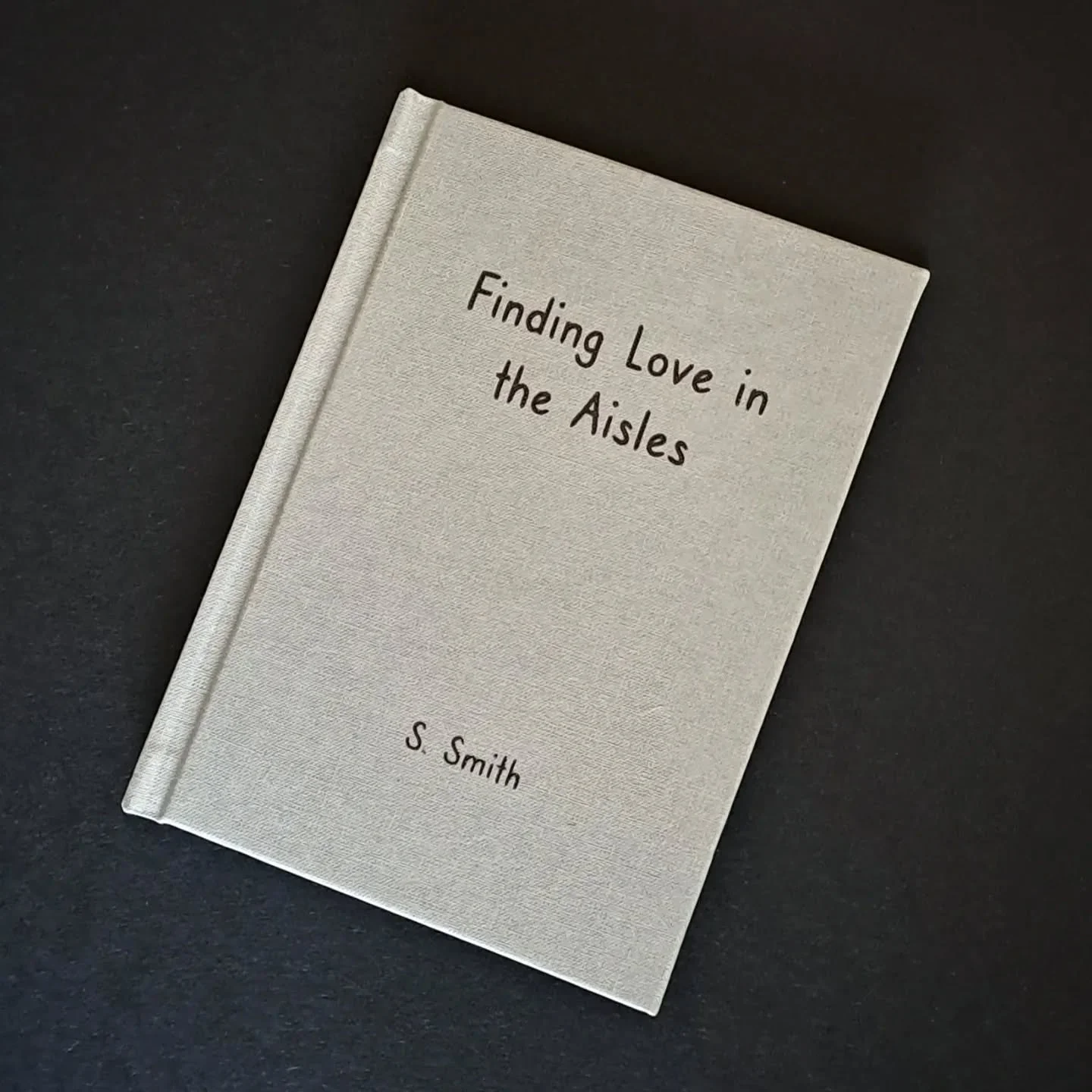

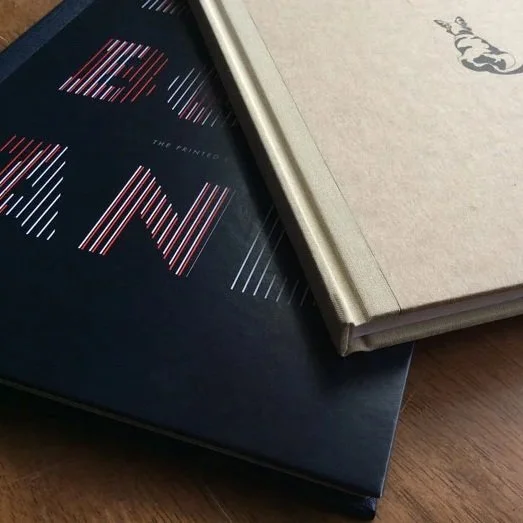

AKA blind deboss / stamping / tooling

Debossing creates a beautiful, recessed impression into the surface of your material. The effect is clean, subtle, highly tactile, adding a sense of quality and permanence without the use of colour.

It's ideal for a sophisticated brand mark, a classic, subtle finish, or for highlighting the natural texture of your chosen material.

You supply a PDF of your custom artwork- The Binding Studio takes care of the rest! To provide you with a quote, Louise needs to view your artwork & positioning choice.

THE PROCESS:

A custom metal block is produced from your artwork

The block is attached to a foiling machine

Heat & pressure are applied to “stamp” the block into the cover

THE SPECIFICS:

Debossing is when a pattern, logo, or title is sunk down into a cover

Depth is determined by layout & design

SUPPLYING ARTWORK:

A high-resolution vector file, coverted to PDF of your logo, text, or artwork

Black artwork on “white” background / no colour or grey scale

100% size / the size you want it on your cover

Positioned on your page size / TBS will add the additional for cover measurements

Lines need to be thicker than half a millimetre / advice will be given on viewing artwork

Very detailed designs may need simplifying / advice will be given on viewing artwork

NOTE: TBS has some brass type available for titles and simple wording. This can be used in place of a custom block for debossing. Ask about “TYPESETTING” for the options.

-

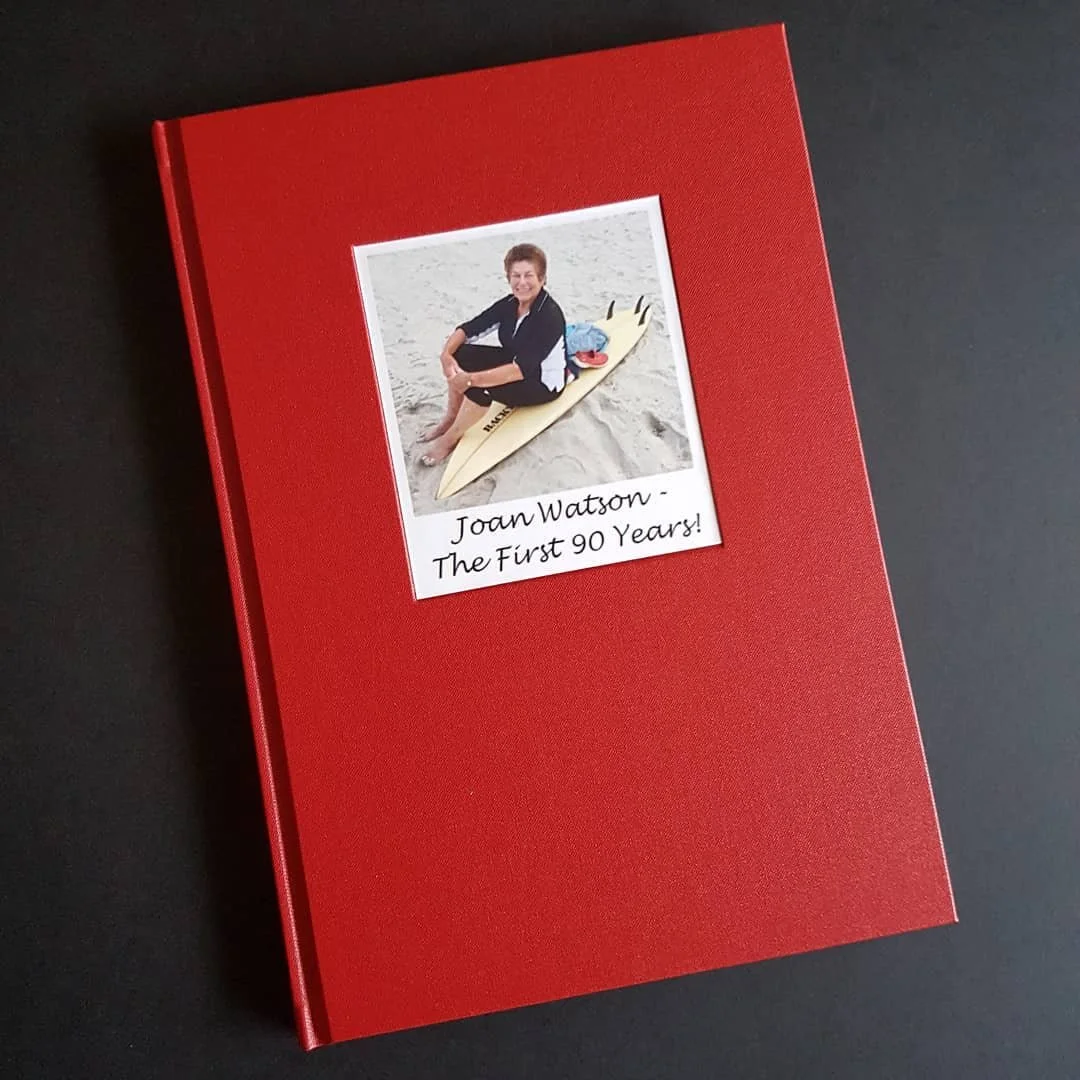

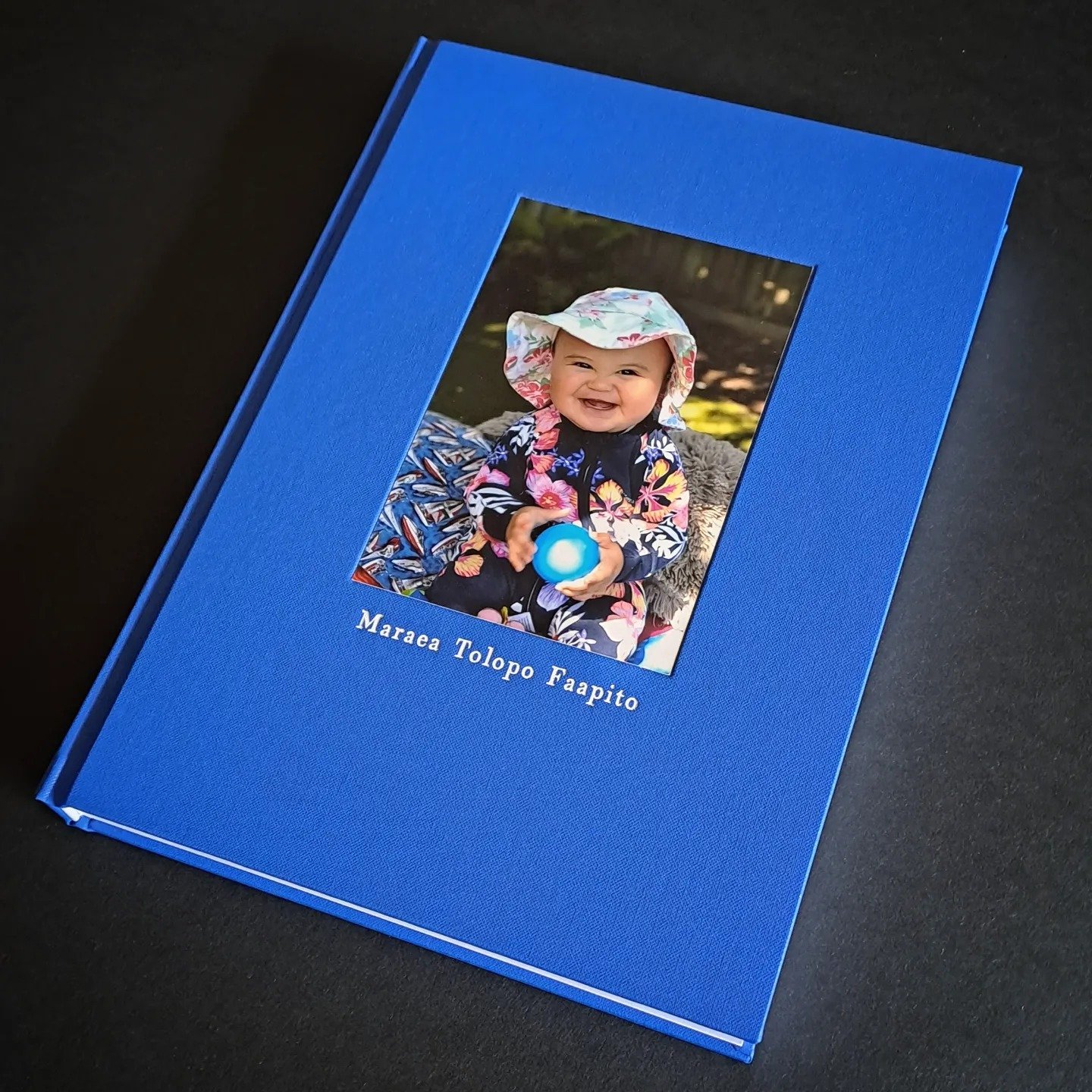

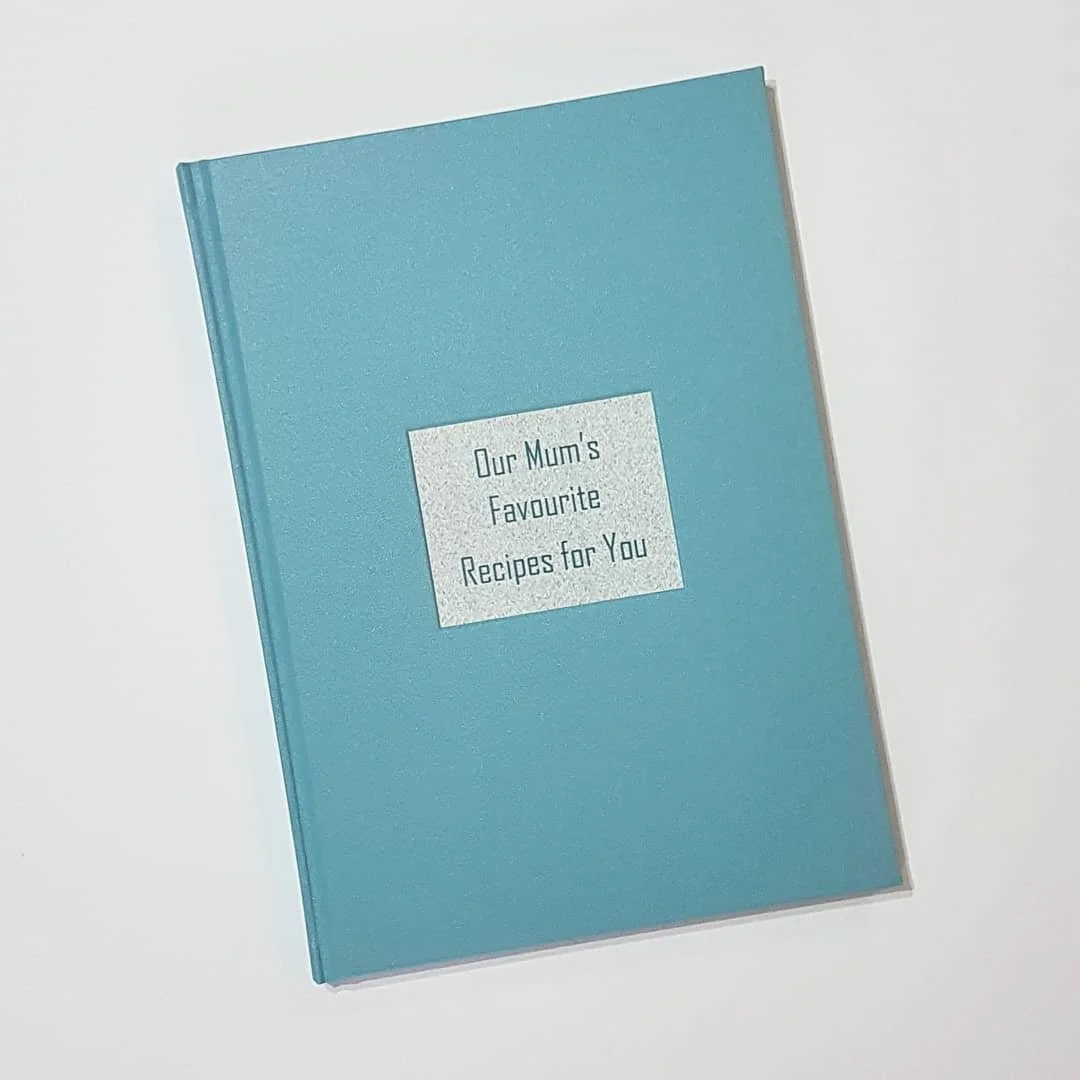

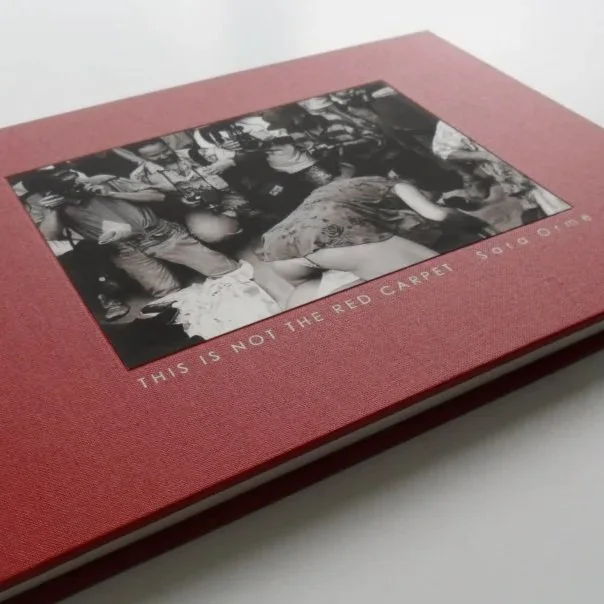

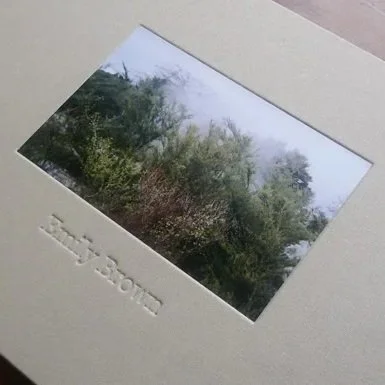

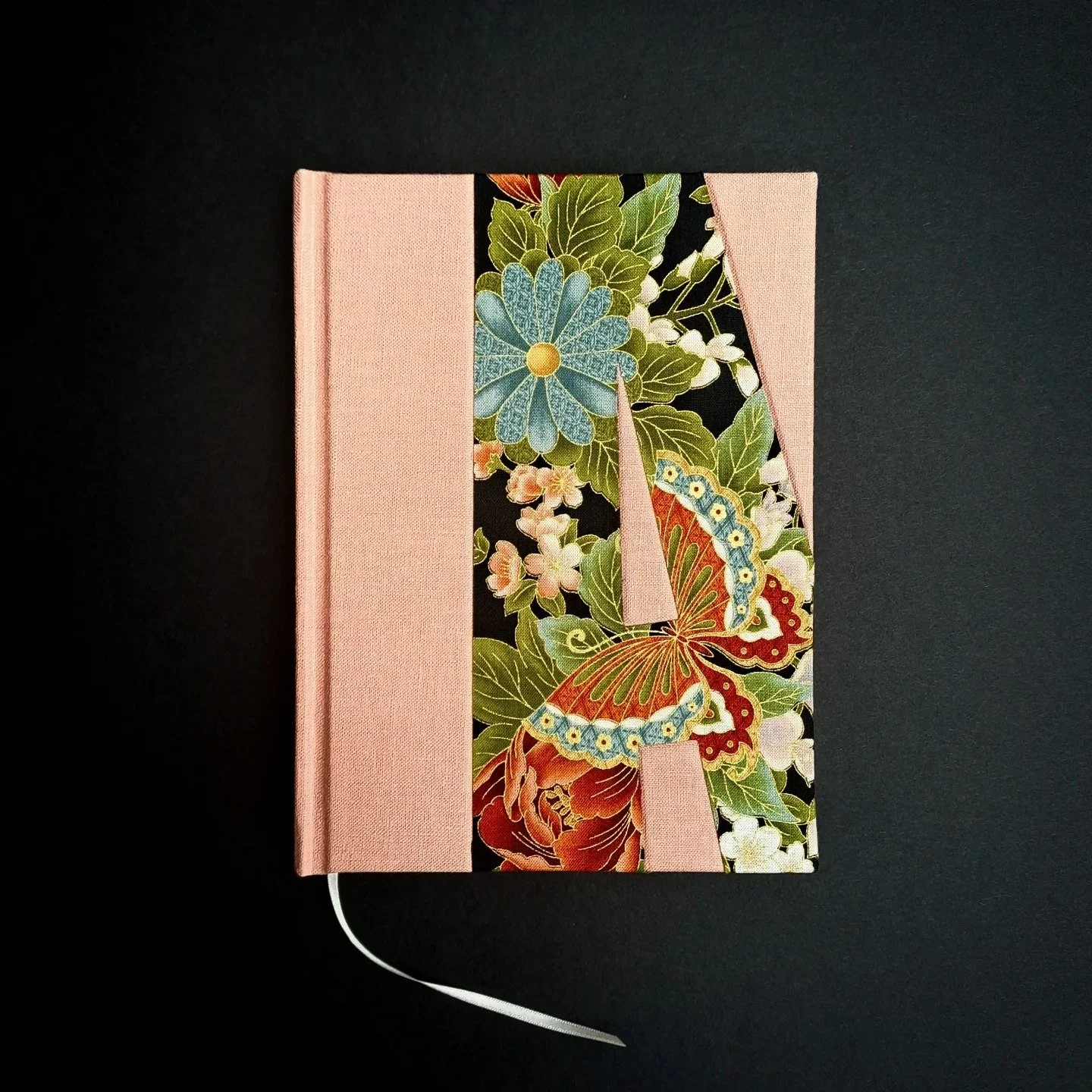

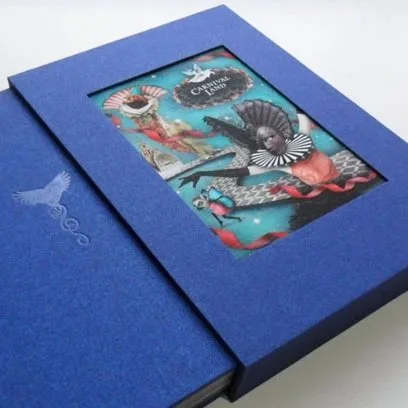

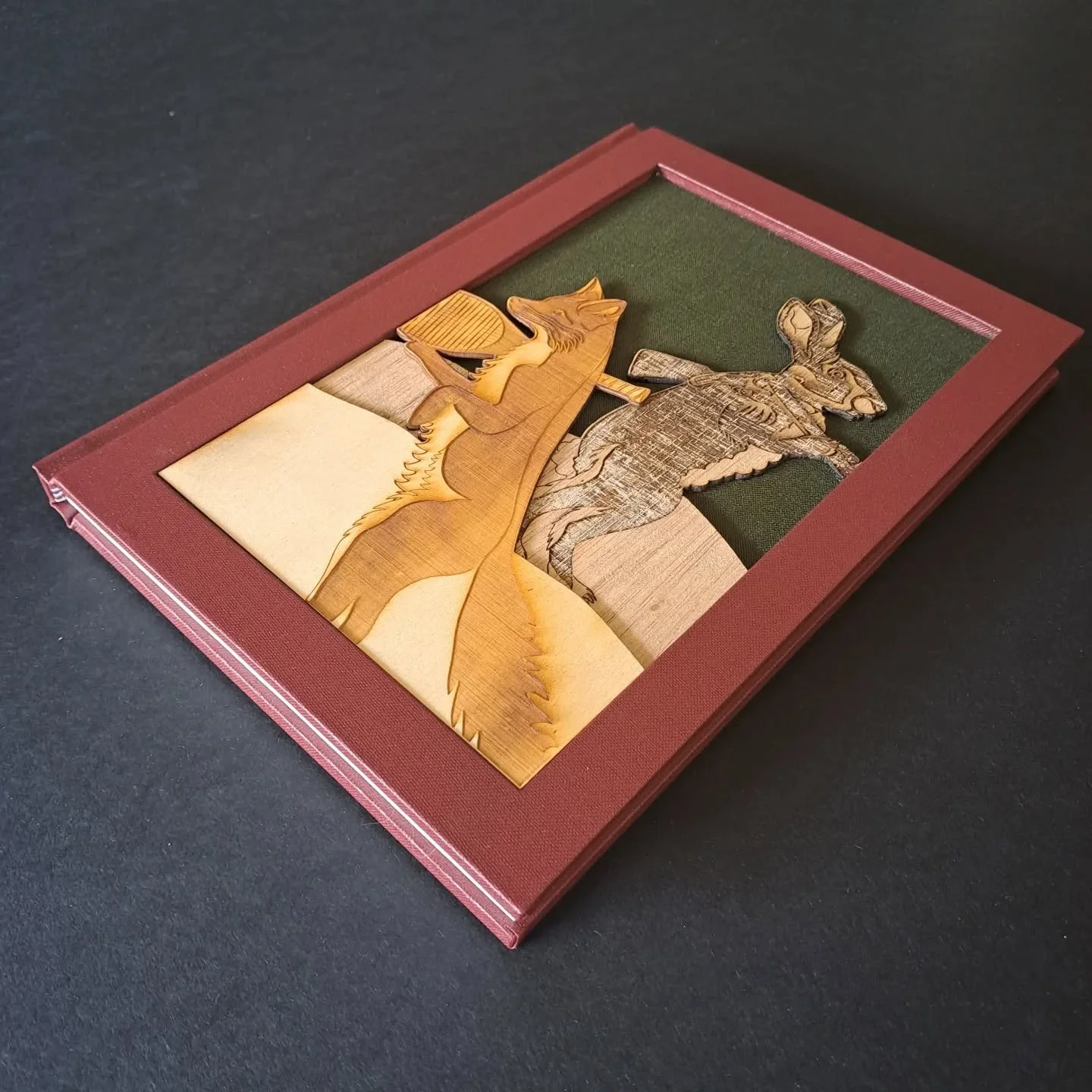

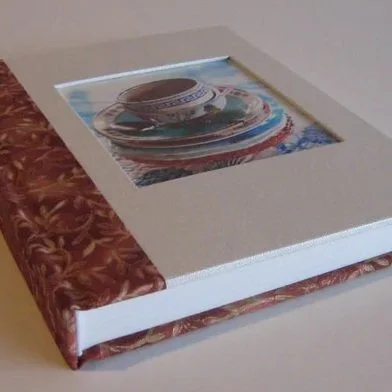

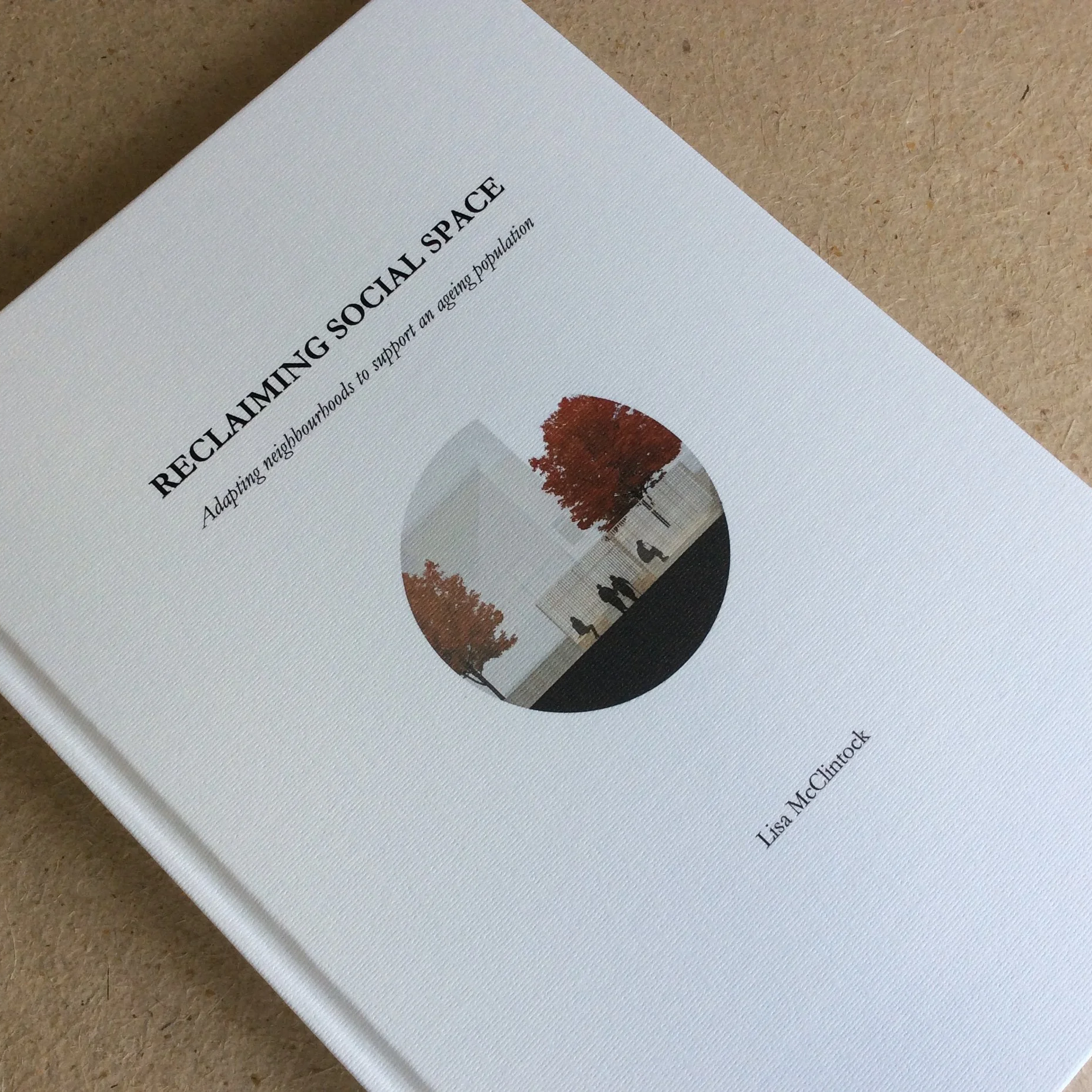

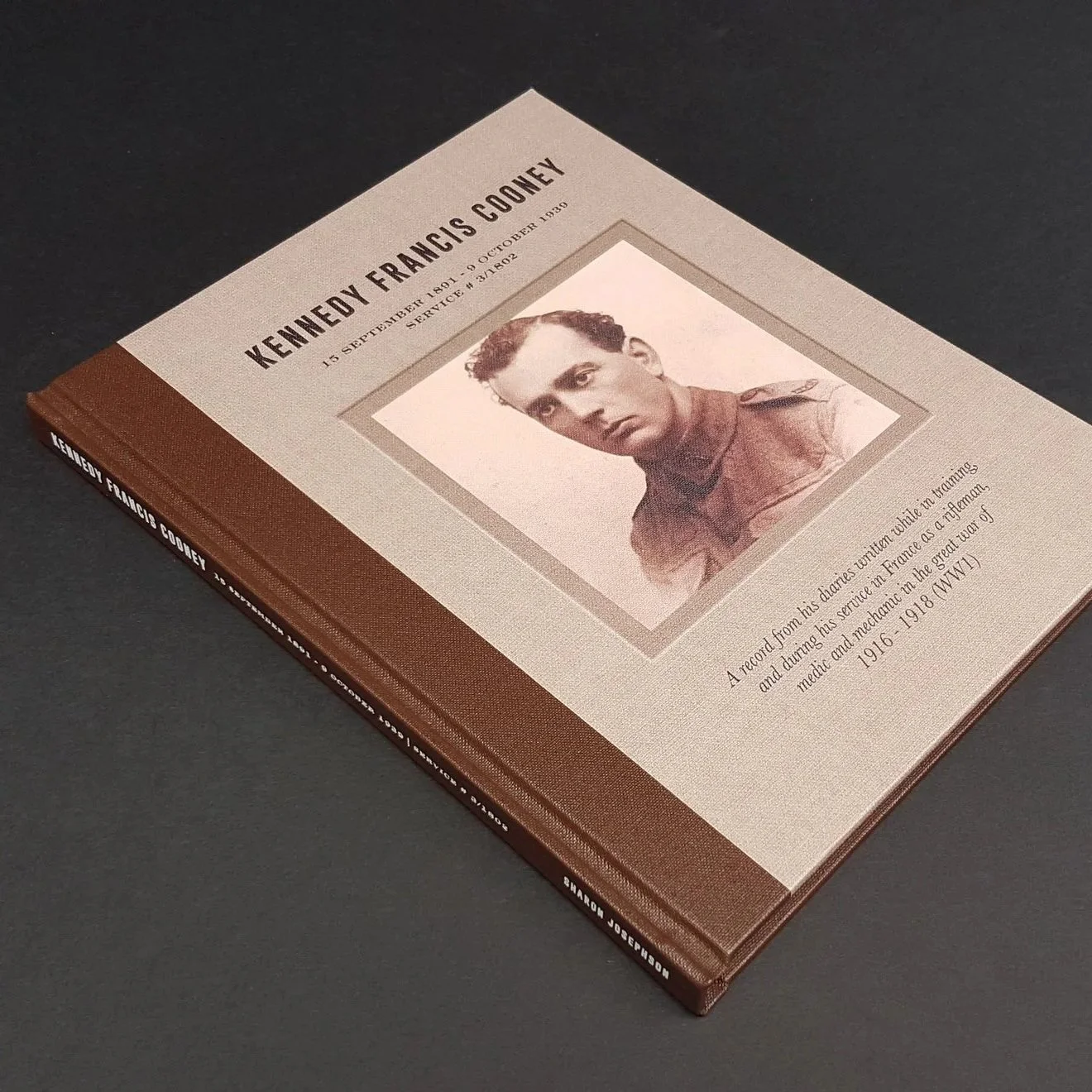

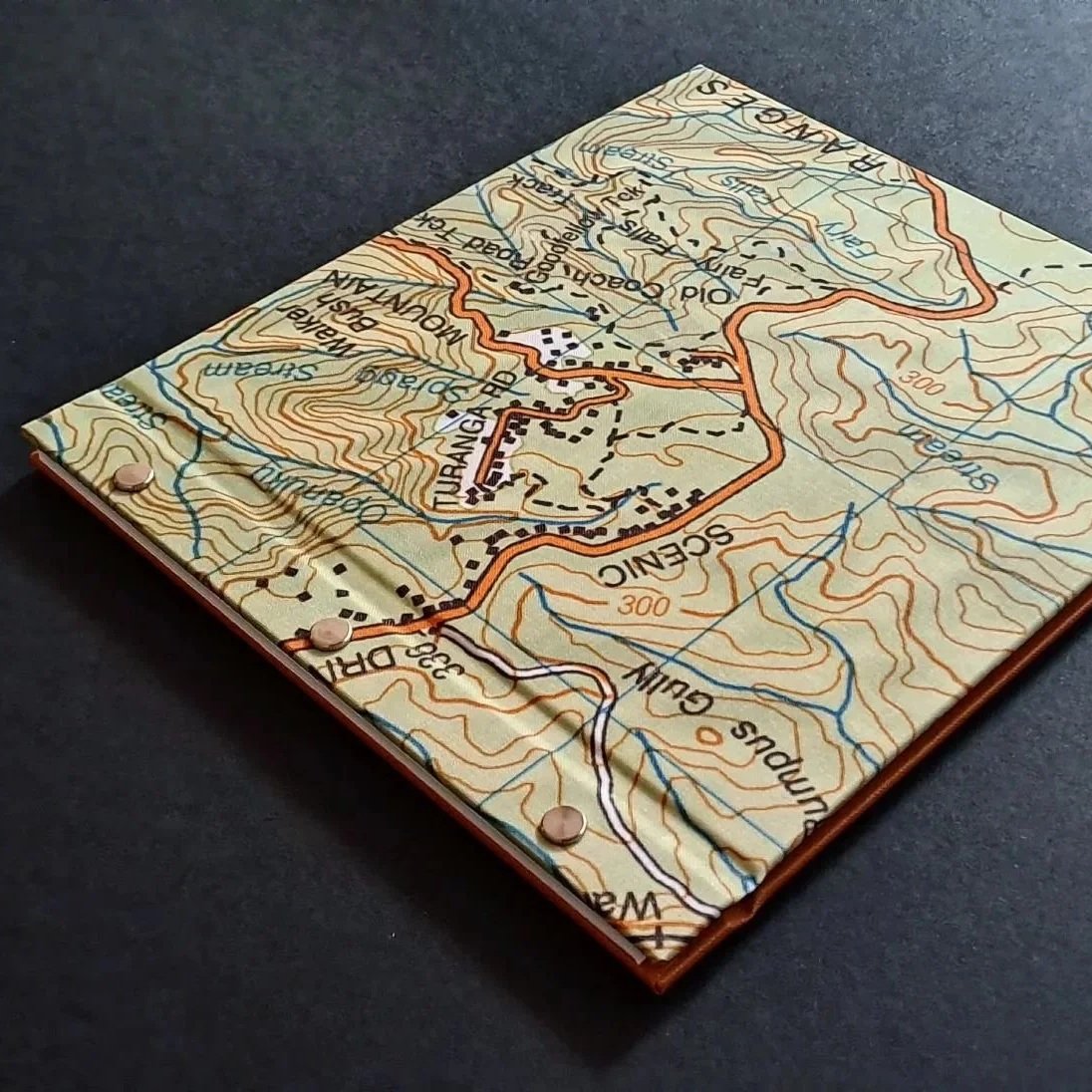

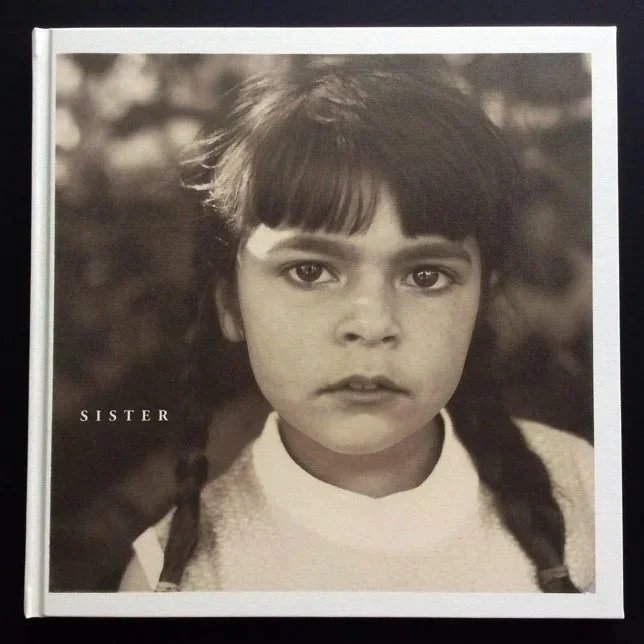

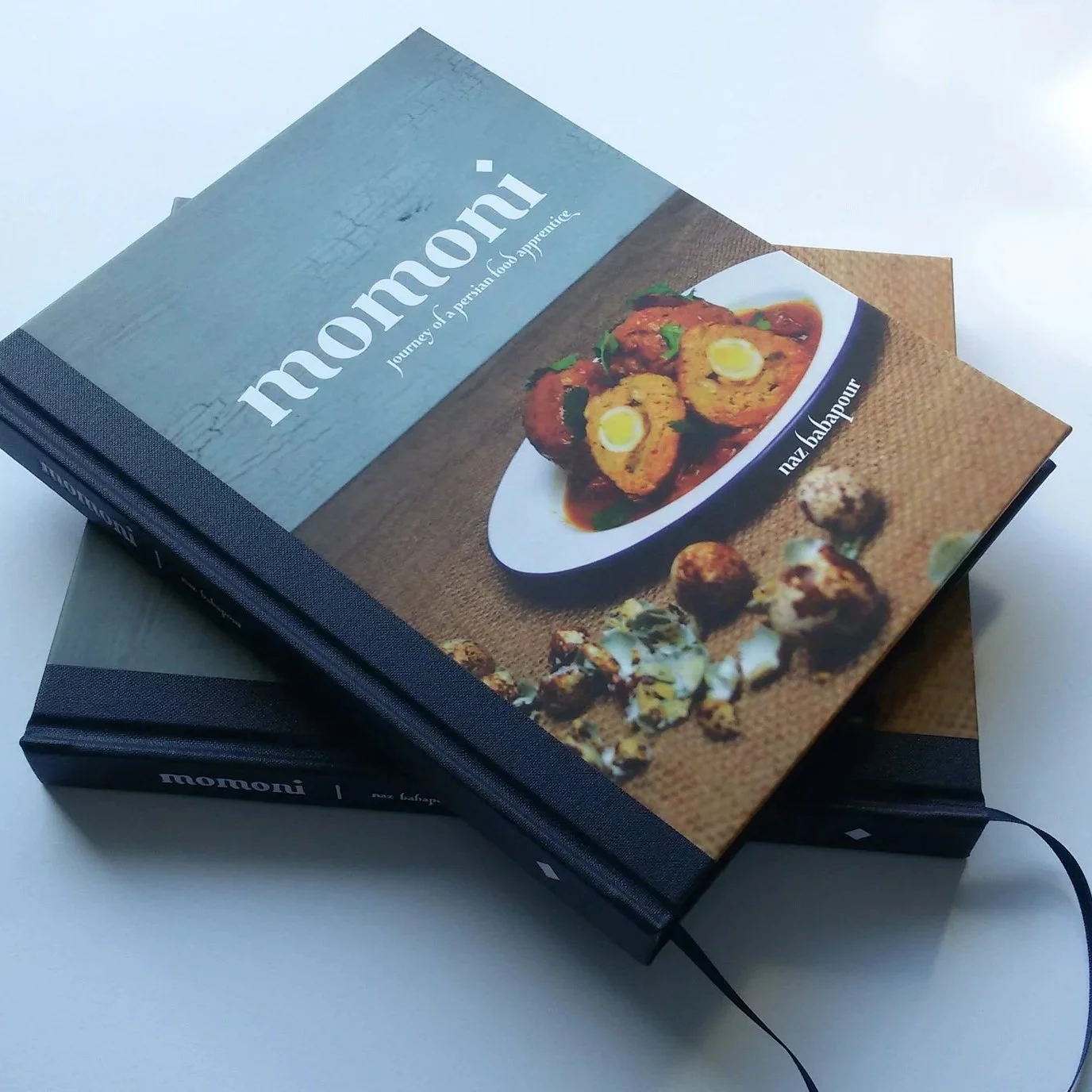

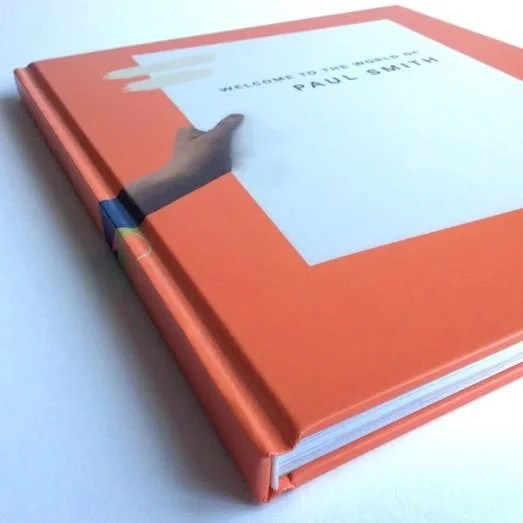

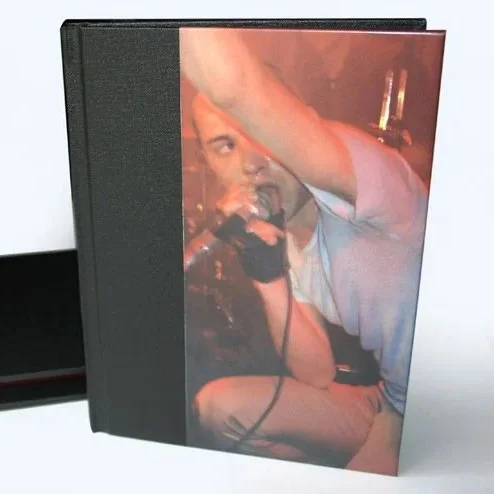

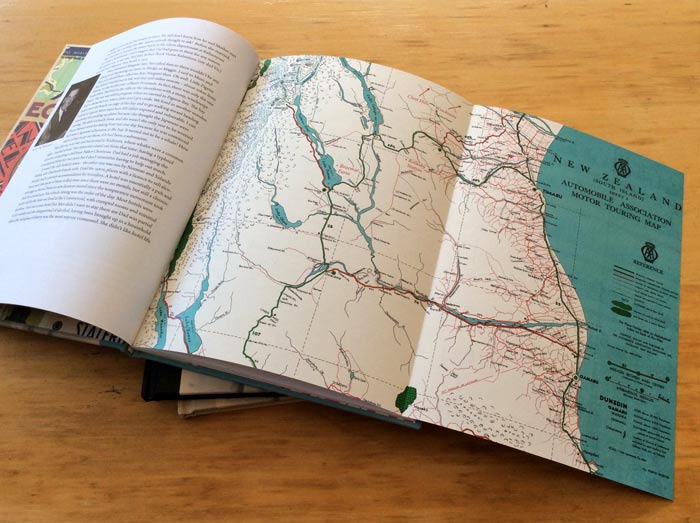

AKA inlay, frame

A recess or insert is an streamlined way to add a feature image to your cover.

The result is a beautifully framed insight into your content. Perfect for images, titles & intricate designs.

You supply a printed image. The Binding Studio takes care of the rest!

RECESS: approx ¾ mm deep, giving a finish almost flush with the cover

INSERT: approx 1.5mm deep, giving a finish akin to a photo frame

THE PROCESS:

Your image is measured and trimmed

A “frame” is created during cover production

The image is adhered into the “frame”

THE SPECIFICS:

Supply an image or photo ready to trim, or at finished size

150gsm paper stock or thicker is recommended

TBS recommends having any image laminated for protection

Ask your printer to supply your image professionally laminated (thinnest possible) on the printed side only

-

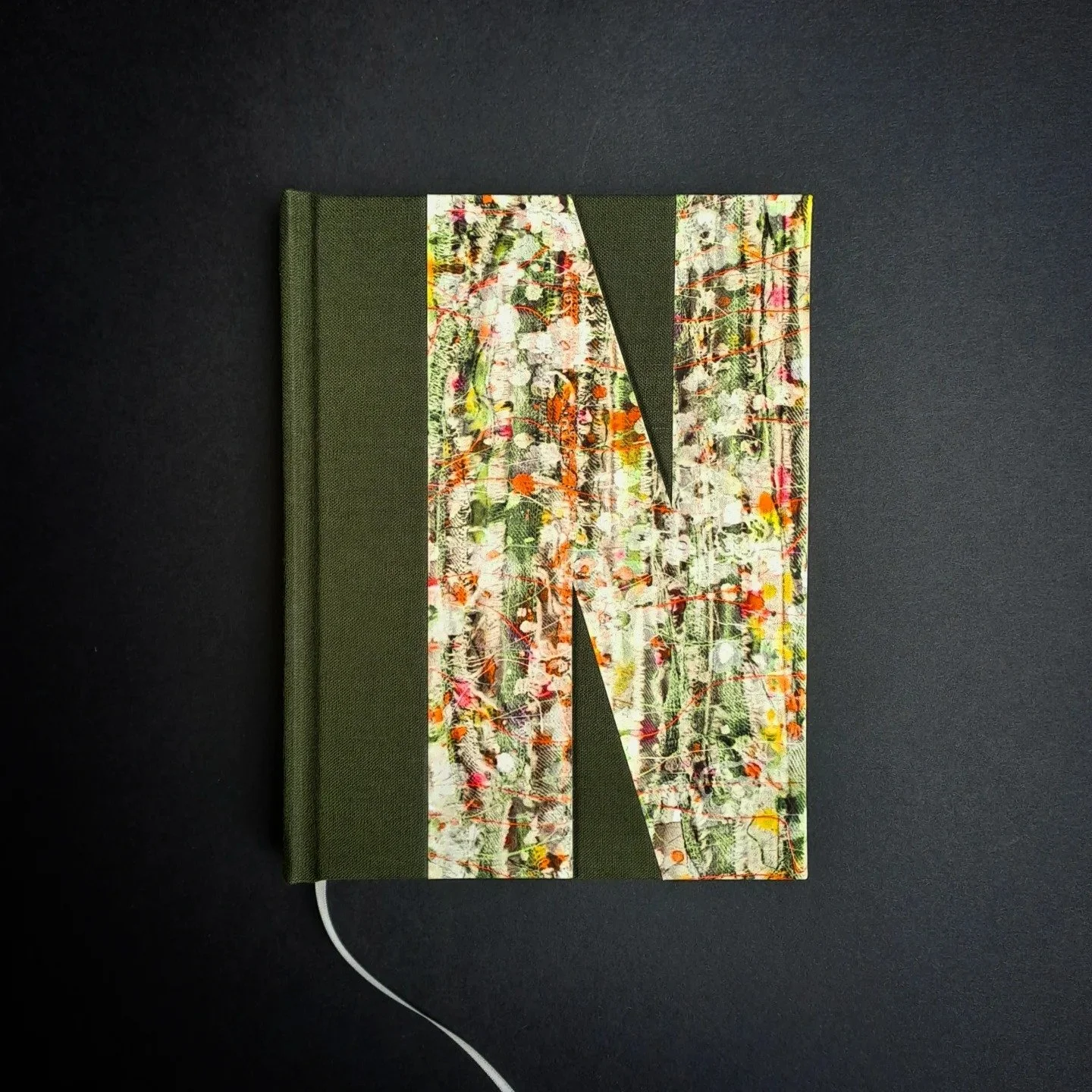

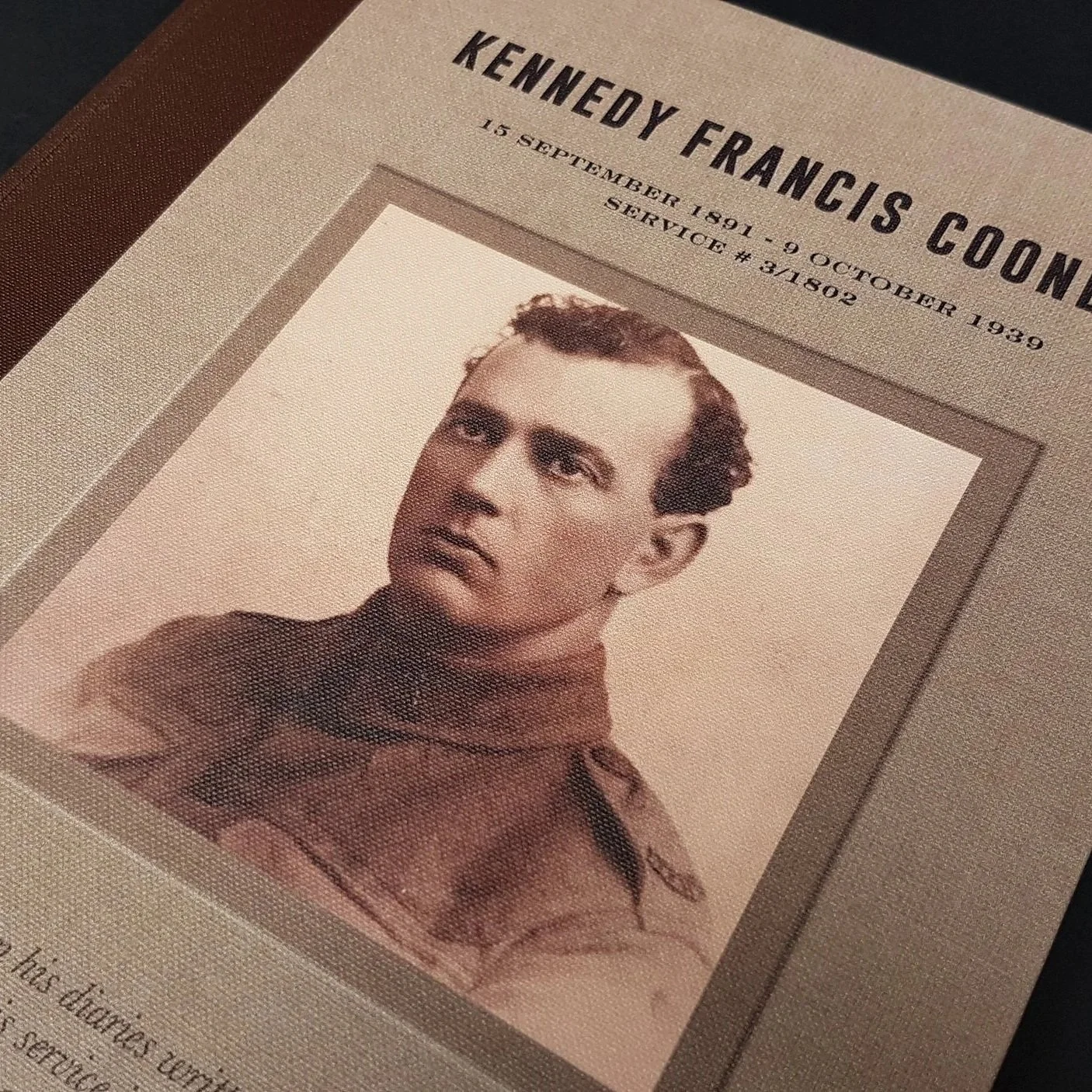

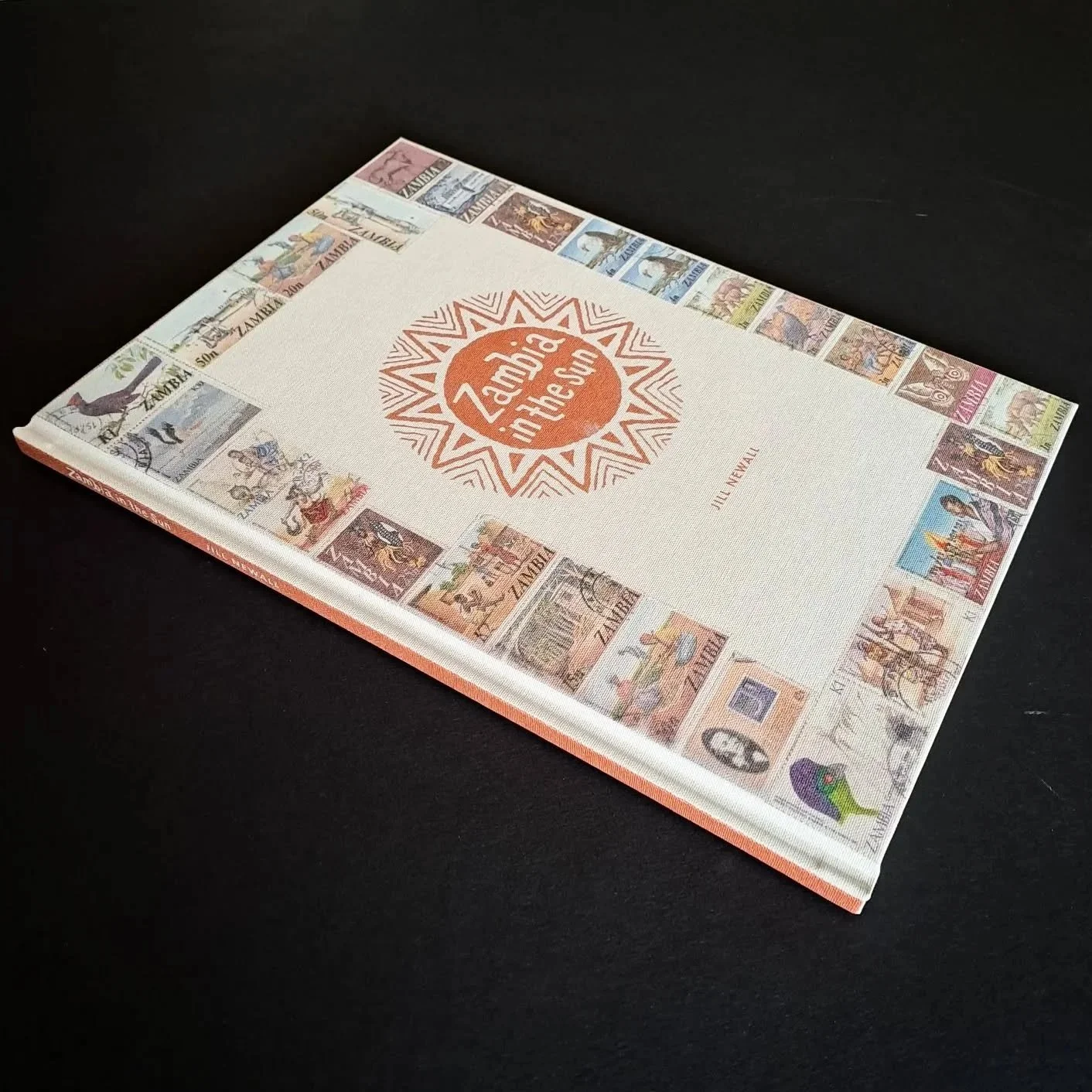

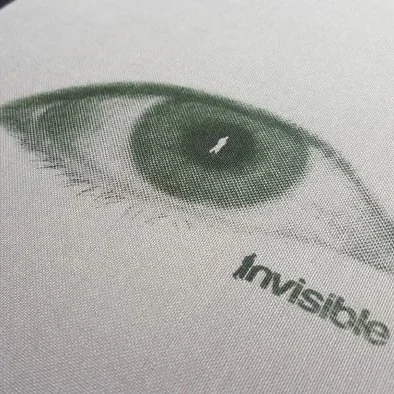

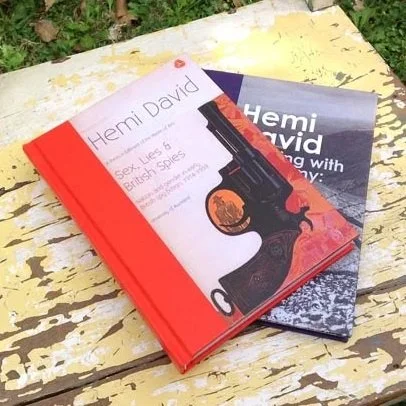

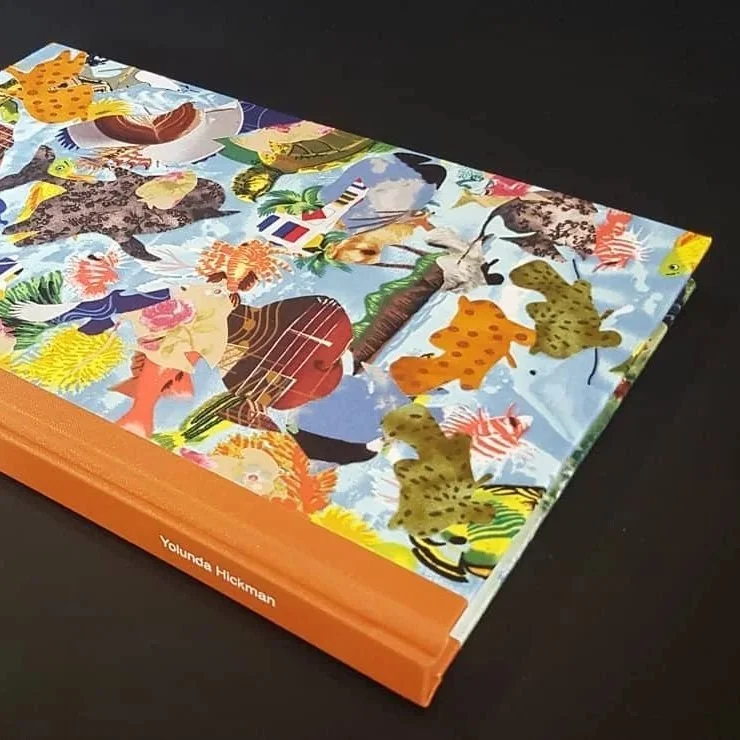

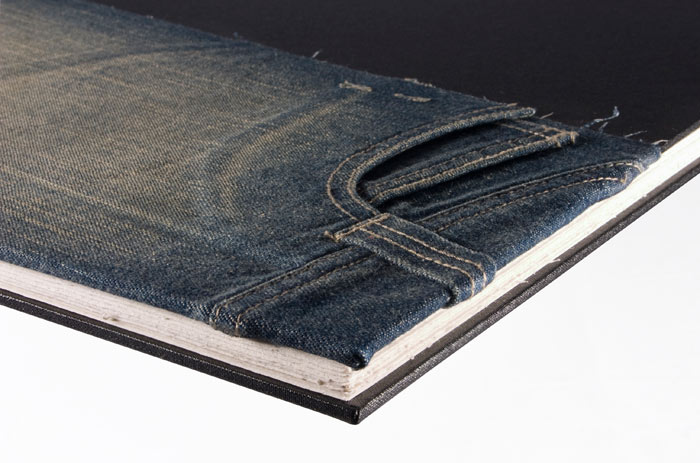

AKA printed cover

Digital cover prints involve printing your design onto book cloth, using a large flat bed printer- usually used for printing billboards.

The result is a great colour match, vibrant and true to your design & long lasting quality.

You supply a PDF of your custom artwork, The Binding Studio takes care of the rest! To provide you with a quote, Louise needs to view your artwork -this can be a rough copy to approx size that you can update later.

THE PROCESS:

Your artwork file is checked against measurements by The Binding Studio

Your artwork and cloth is sent to the printer

Your artwork is printed onto the cloth of your choice (usually white) & sent back to TBS

The cover boards are adhered to the cloth, aligning with your design

THE SPECIFICS:

TBS will provide a layout guide determined by your page size and depth

You supply a high-resolution vector file, coverted to PDF of your artwork

This needs to include crop marks at the 4 outer corners only

-

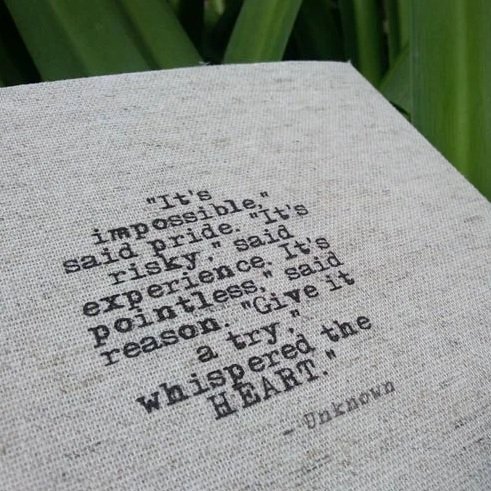

AKA t-shirt transfer

Heat transfer involves printing your design onto clear transfer paper & applying it to the light coloured cloth of your choice in a heat press.

The result is a cost effective way to have a design on your cover. Perfect for titles, logos & intricate designs.

You supply a PDF of your custom artwork- The Binding Studio takes care of the rest! To provide you with a quote, Louise needs to view your artwork & positioning.

THE PROCESS:

Your artwork is printed onto transfer paper

The transfer is applied to book cloth using a heat press

The cover boards are adhered to the cloth, aligning with your design

THE SPECIFICS:

Can be applied to a cover A4 or smaller

Light coloured book cloths give the best outcome

100% colour matching is not guaranteed due to the standard printer used & multiple processes applied

SUPPLYING ARTWORK:

Supply a high resolution PDF

100% size / the size you want it on your cover

Positioned on your page size / TBS will add the additional for cover measurements

Alternatively Lou can supply a layout guide for exact positioning

-

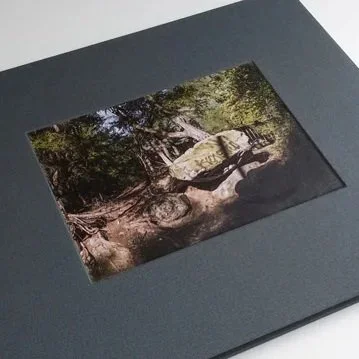

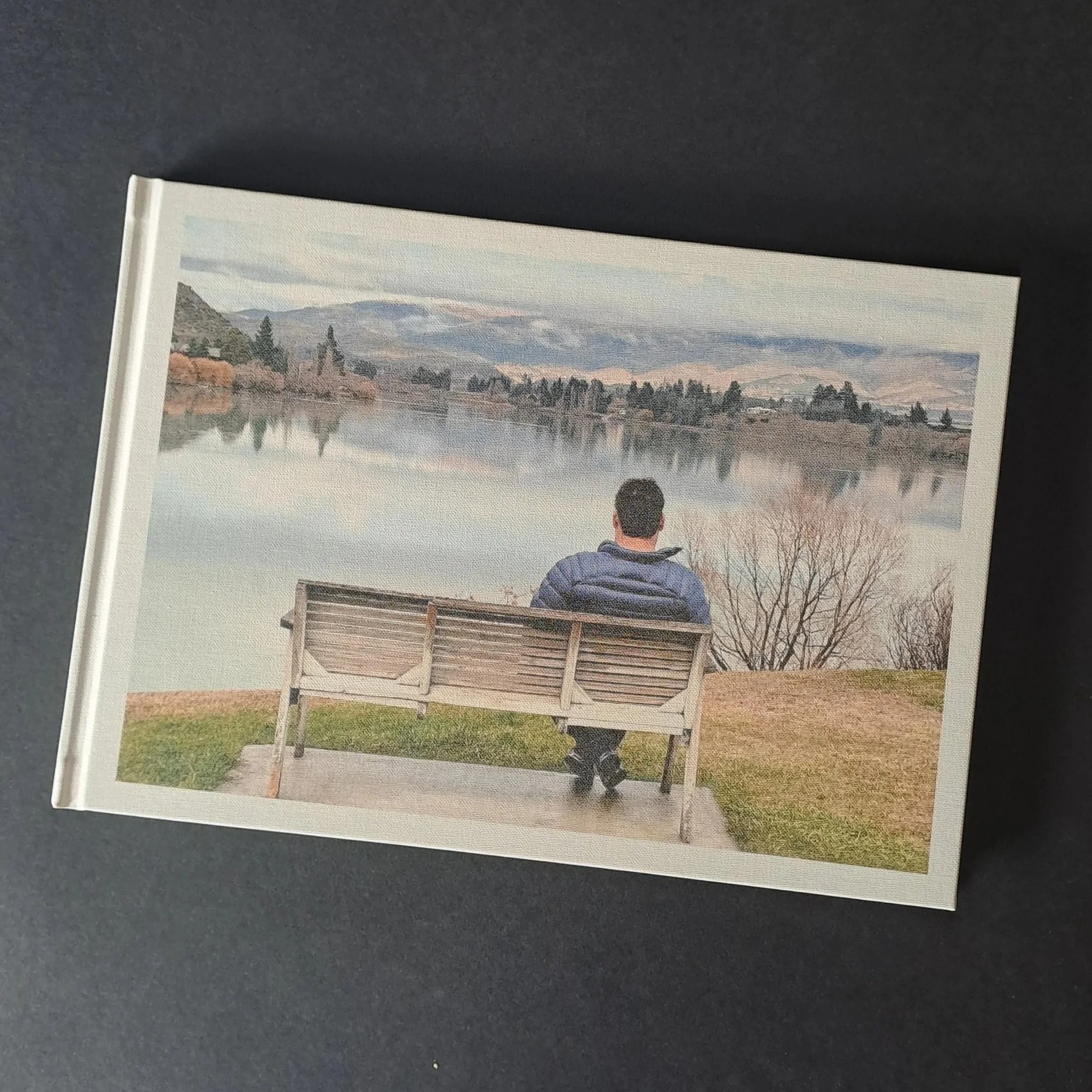

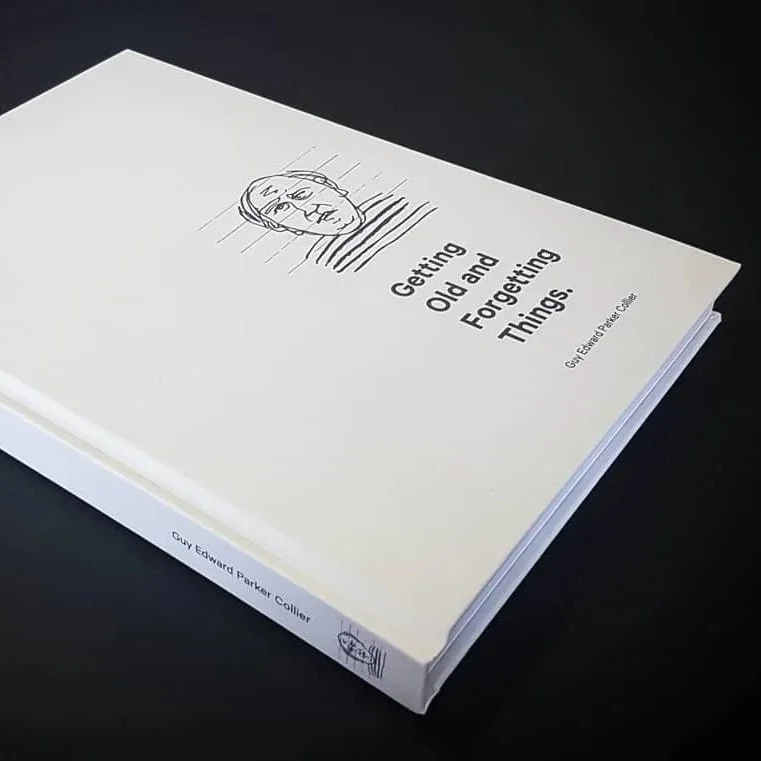

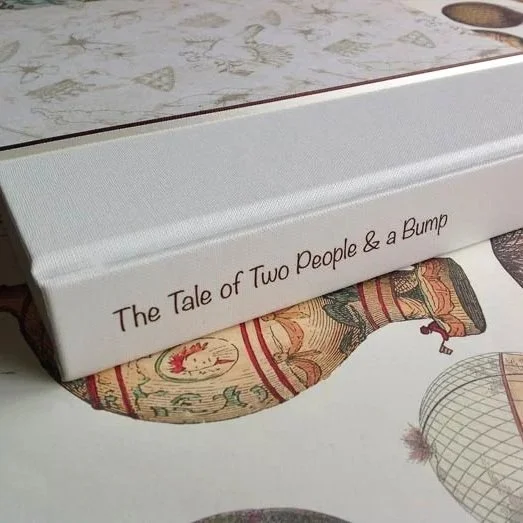

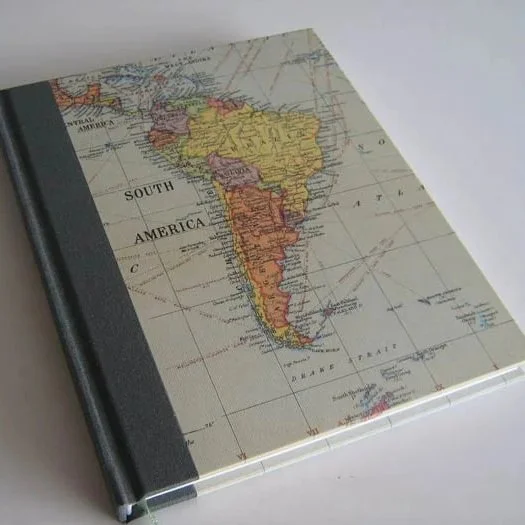

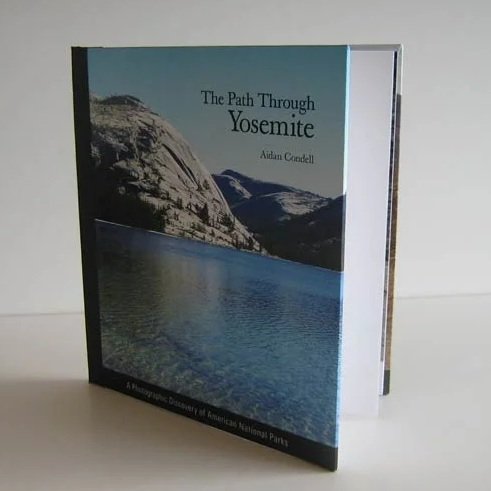

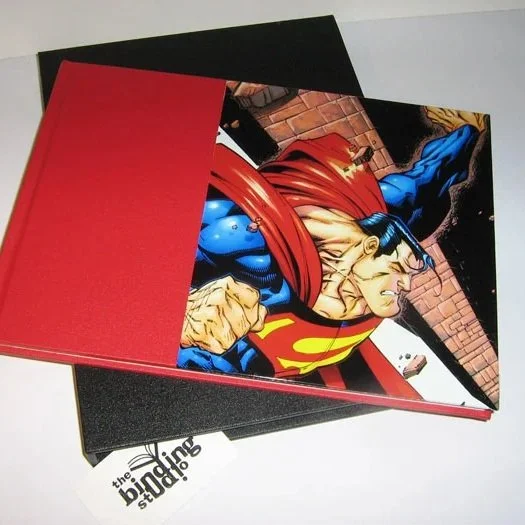

AKA printed case wrap, printed cover

Image wrap involves printing your design onto paper, having it laminated and using that as the cover material.

The result is a cost effective way to have a design on your cover. Perfect for titles, logos & intricate designs.

You supply the physical print of your custom artwork- The Binding Studio takes care of the rest!

THE PROCESS:

Your artwork is printed onto paper

The paper is laminated on the printed side only

The cover boards are adhered to the paper, aligning with your design

THE SPECIFICS:

TBS recommends using the front & back of a book only & having a cloth spine to avoid tears in the hinges

TBS will provide a layout guide determined by your page size and depth

SUPPLYING PRINTS:

Supply prints with crop marks marking the outer corners (untrimmed)

120gsm paper stock or thicker is recommended

Paper grain to run with the spine

Ask your printer to supply your print professionally laminated (thinnest possible) on the printed side only

Supply extras (exact number determined by quantity)

-

custom box linings

closures

unique coverings

raised bands

custom fabric / materials

ribbon detailing

pockets

custom endpapers / fold outs

or any other detail- everything is possible!